From Humble Beginnings to High-Tech Guardians: The Evolution of Forklift Safety

The forklift, a ubiquitous presence in warehouses and factories worldwide, has undergone a remarkable transformation over the past 125 plus years. What began as a simple labor-saving device has evolved into a sophisticated machine, with safety at the forefront of its design and operation. This blog delves into the fascinating history of forklifts, highlighting the groundbreaking advancements that have made these workhorses significantly safer for both operators and pedestrians in their environment.

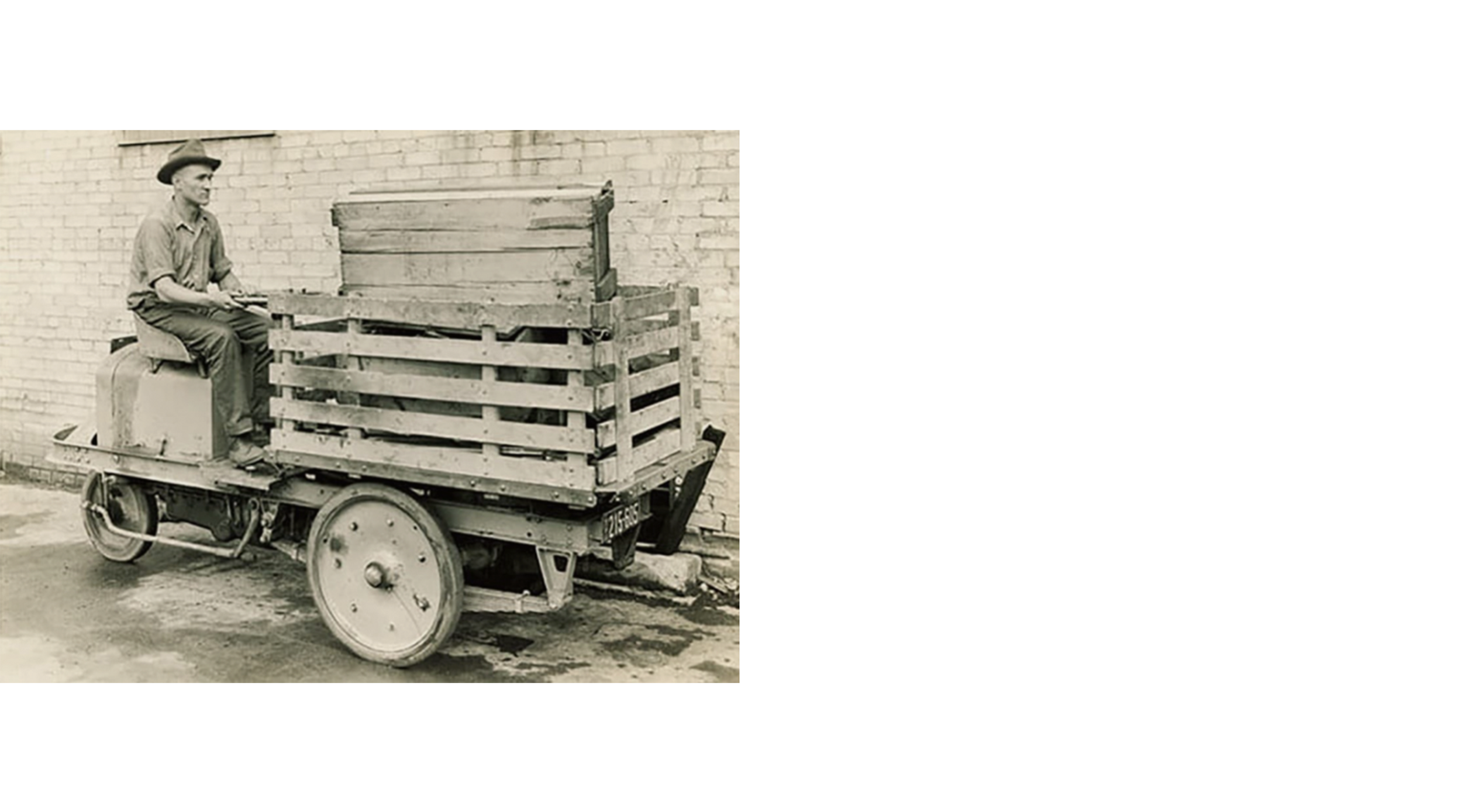

The Early Days: Necessity Breeds Innovation

In the early 20th century, the world was grappling with the challenges of World War I, including labor shortages that threatened to cripple industrial productivity. It was in this climate of necessity that the concept of the forklift was born. In 1917, Eugene Clark unveiled the "Tructractor," widely regarded as the first forklift, albeit lacking the iconic forks we associate with modern versions. While revolutionary in its ability to move heavy materials efficiently, safety features were virtually nonexistent in these early prototypes.

The Interwar Period: Advancements and Efficiency

The years between World War I and World War II witnessed a surge in forklift development. Hydraulics were incorporated, allowing for vertical lifting, and the signature forks became a permanent fixture. The demands of World War II further accelerated advancements, as the need for rapid material handling intensified. However, during this period, the focus remained primarily on efficiency and productivity, with safety concerns taking a backseat.

The 1950s and 60s: Safety Enters the Equation

As forklifts increased in lifting capacity and maneuverability, concerns about operator safety began to surface. Accidents involving rollovers, falling objects, and crushing injuries raised red flags within the industry. But it wasn't until the 1950s and 60s that manufacturers started introducing basic safety features like overhead guards and load backrests. These rudimentary safeguards offered some level of protection for operators, but the risk of collisions with pedestrians remained a significant concern.

Ergonomics and Operator Comfort: A New Frontier

The 1980s marked a shift towards operator well-being, with operator safety and ergonomic design principles becoming a priority. Features like seatbelts and improved visibility through masts became commonplace. These advancements not only enhanced safety but also led to increased productivity and reduced operator errors, underscoring the inextricable link between safety and efficiency.

The Pedestrian Safety Challenge: A Pressing Concern

Despite significant advancements in operator safety, one critical area remained largely unaddressed – pedestrian safety. Forklifts operate in dynamic environments with a high volume of foot traffic, and limited visibility and blind spots often lead to accidents, with pedestrians bearing the brunt of injuries. In fact, interactions with forklifts are one the most common causes of accident and injury to pedestrian workers. This became a pressing concern as warehouses and factories sought to create safer working environments for all personnel and regulators increasingly turned their attention to workplace safety around MHE.

Pedestrian alert safety systems: Redefining Forklift Safety in the 21st Century

Addressing the pedestrian safety challenge, innovative pedestrian alert safety systems have emerged, redefining forklift safety standards. Initially these involved largely “passive” systems such as blue lights, however solutions have increasingly utilized advanced radar, camera technology, and sensor fusion to create virtual safety zones around forklifts. When a pedestrian enters this zone, the system provides active warnings to the operator and pedestrian alike, prompting them to slow down or stop, effectively preventing collisions before they occur.

Pedestrian alert safety systems represent a paradigm shift, tackling a long-standing issue that has plagued the industry. By minimizing accidents and injuries involving pedestrians, these systems foster safer working environments for everyone, operators and pedestrians alike.

A Culture of Safety: The Driving Force

While technological advancements have played a pivotal role in enhancing forklift safety, creating a culture of safety within organizations is equally crucial. Investing in cutting-edge solutions like Seen Safety's pedestrian detection system demonstrates a commitment to prioritizing the well-being of all personnel within a warehouse or industrial setting. It's not just about compliance; it's about fostering a mindset that values safety as an integral part of daily operations.

Continuous Improvement: A Journey towards zero harm

As we look to the future, the journey towards achieving zero accidents and injuries in forklift operations continues. The history of forklifts serves as a testament to human ingenuity and the relentless pursuit of safety. From the rudimentary safeguards of the early days to the sophisticated technology of today, we have come a long way, but there is always room for improvement.

Collaboration between manufacturers, safety experts, and end-users will be key to identifying areas for further enhancement. Advancements in sensor technology hold immense potential for creating even safer working environments. Additionally, ongoing training and education for operators and pedestrians alike will reinforce the importance of safety protocols and responsible practices.

Conclusion: The Future of Forklift Safety

The history of forklift safety is a remarkable journey, one that has transformed these machines from mere labor-saving devices into high-tech guardians of worker safety. As we continue to push the boundaries of innovation, we must remain steadfast in our commitment to creating safer workplaces for all. By embracing cutting-edge solutions like Seen Safety's pedestrian detection system and fostering a culture of safety, we can pave the way for a future where accidents and injuries are a distant memory, and productivity and well-being go hand in hand.