Reflective Tape Requirements for High-vis Workwear

IRIS 860 sensors use advanced infrared LIDAR technology to detect retroreflective tape applied to PPE and other objects in the workplace. These sensors are specifically optimized to reliably detect standard Class II high-visibility day/night PPE in real-world conditions, with built-in tolerance for normal wear and tear.

How Much Reflective Tape is Needed?

The exact amount of reflective tape needed for detection at any given distance varies according to a number of factors:

The distance from the sensor to the tape.

The retroreflective performance of the tape (its quality).

The angle of the tape relative to the sensor (signal strength decreases as the angle increases).

The condition of the tape (wear and tear).

If your day/night PPE cannot be detected by an IRIS 860 sensor it indicates it’s unlikely to meet the minimum requirements for personal protective equipment (PPE). To ensure reliable detection, ensure the garment has sufficient retroreflective tape to allow detection from any angle at the required maximum detection distance, and beyond.

If in doubt, we recommend using an IRIS 860 sensor to thoroughly check your workplace PPE in advance of any implementation.

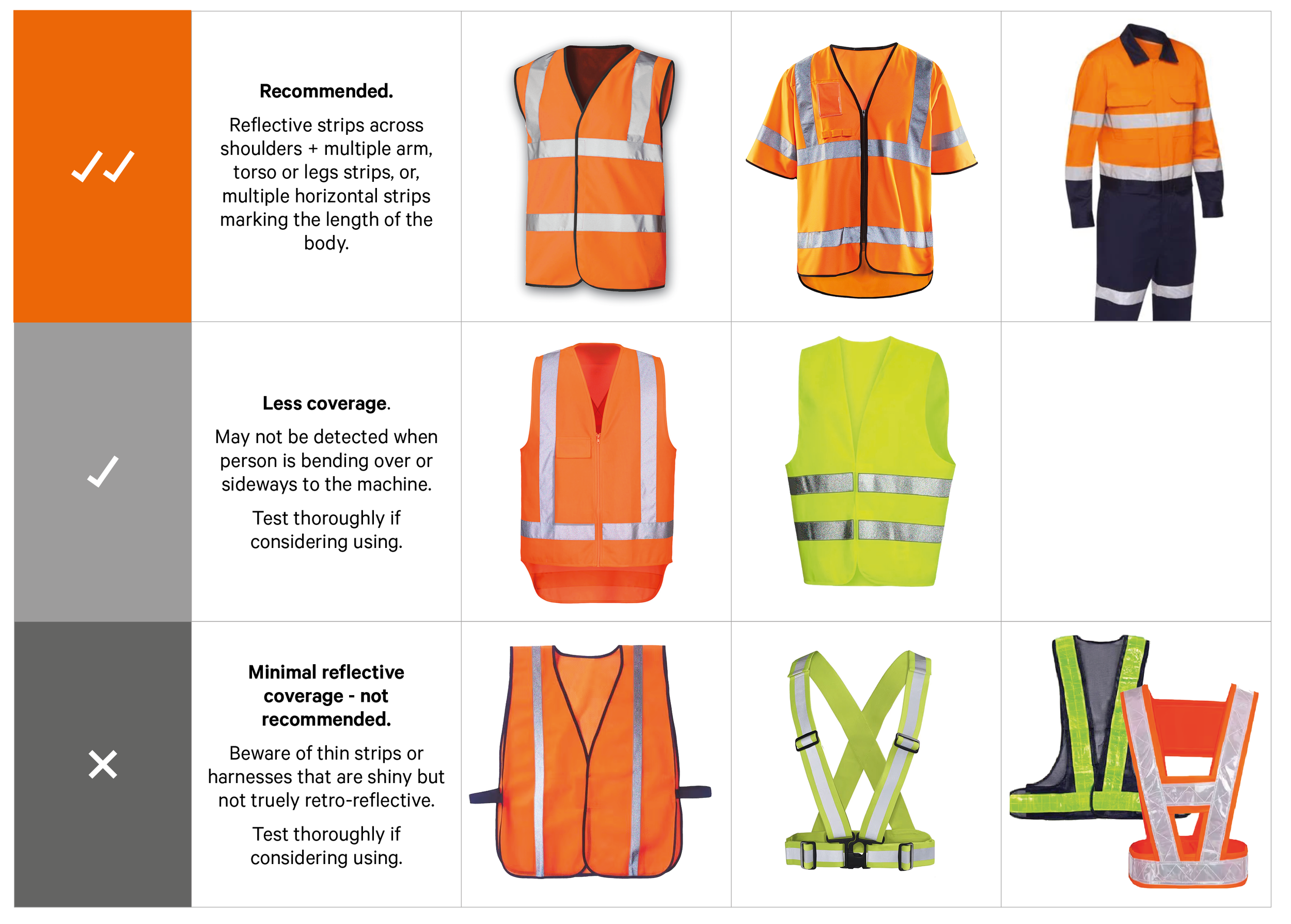

What types of PPE are recommended?

Other Important Factors

Impact of Wear and Tear

Over time, abrasion will gradually dislodge the retroreflective glass beads which slowly reduces the retroreflective performance.

Heavily worn tape is unlikely to meet safety standards and should be replaced.

As tape performances degrades it will reduce the effective detection distance of the sensor. Garments that cannot be detected at the required distance are overdue for replacement.

High-viz Company Uniforms

Company issued high-visibility apparel is sometimes used as a substitute for PPE. These garments tend to be washed more frequently than would a high-vizibility vest, and may also feature a less than ideal amount of retroreflective tape.

While reliable detection can be often achieved, always test your uniforms with a SEEN sensor to confirm performance.

The Effect of Washing

Each wash cycle will slightly degrade the retroreflective tape. Standards-compliant garments specify the number of wash cycles they can withstand before falling below compliance—typically around 50 cycles, but this varies. Always check the garment label for washing limits.

While an item of PPE can often still be detected by a SEEN sensor beyond its rated number of wash cycles, this should be regularly checked. Frequently laundered items (such as overalls, high-vis tee shirts, and uniforms) should be tested and replaced as needed.

Compliance with Standards

To ensure optimal detectability ensure your PPE meets recognized high-visibility standards, such as: EN ISO 20471:2013, ANSI/ISEA 107:2020, AS/NZS 4602.1:2011, JIS T 8127:2020, or the equivalent standard in your country. SEEN sensors are optimized to detect Class 2 and Class 3 types of PPE.

Retroreflectivity Check

To quickly check if something is retroreflective, or to ensure the tape used is truly retroreflective, and not merely decorative:

Put the item in a dark environment and illuminate it with a flashlight (or other light source) inline with your eyes. Retroreflective materials will glow bright white because they reflect the light back towards its source—and your eyes.

Alternatively use an IRIS 860 sensor to check for detection at the desired distance.

Questions

For more information please refer to our SEEN High-Viz Requirements Guide (PDF)

If you have any questions or concerns about whether your workwear has sufficient reflective tape please email support@seensafety.com.