Reflecting on Safety - A Field Guide to Retroreflective PPE and Markings

Why retroreflective materials matter

For people working in high-risk environments, high-visibility PPE is essential so others can see them clearly. Effective hi-vis apparel typically combines:

Bright, fluorescent fabric (often yellow-green or orange) to boost daytime visibility, and

Retroreflective bands that return light toward its source for visibility at night and in low-light conditions.

While the bright colors are self-explanatory; the reflective bands are less obvious. This guide explains retroreflection—what it is, how it works, and how to use it effectively.

What is a retroreflector?

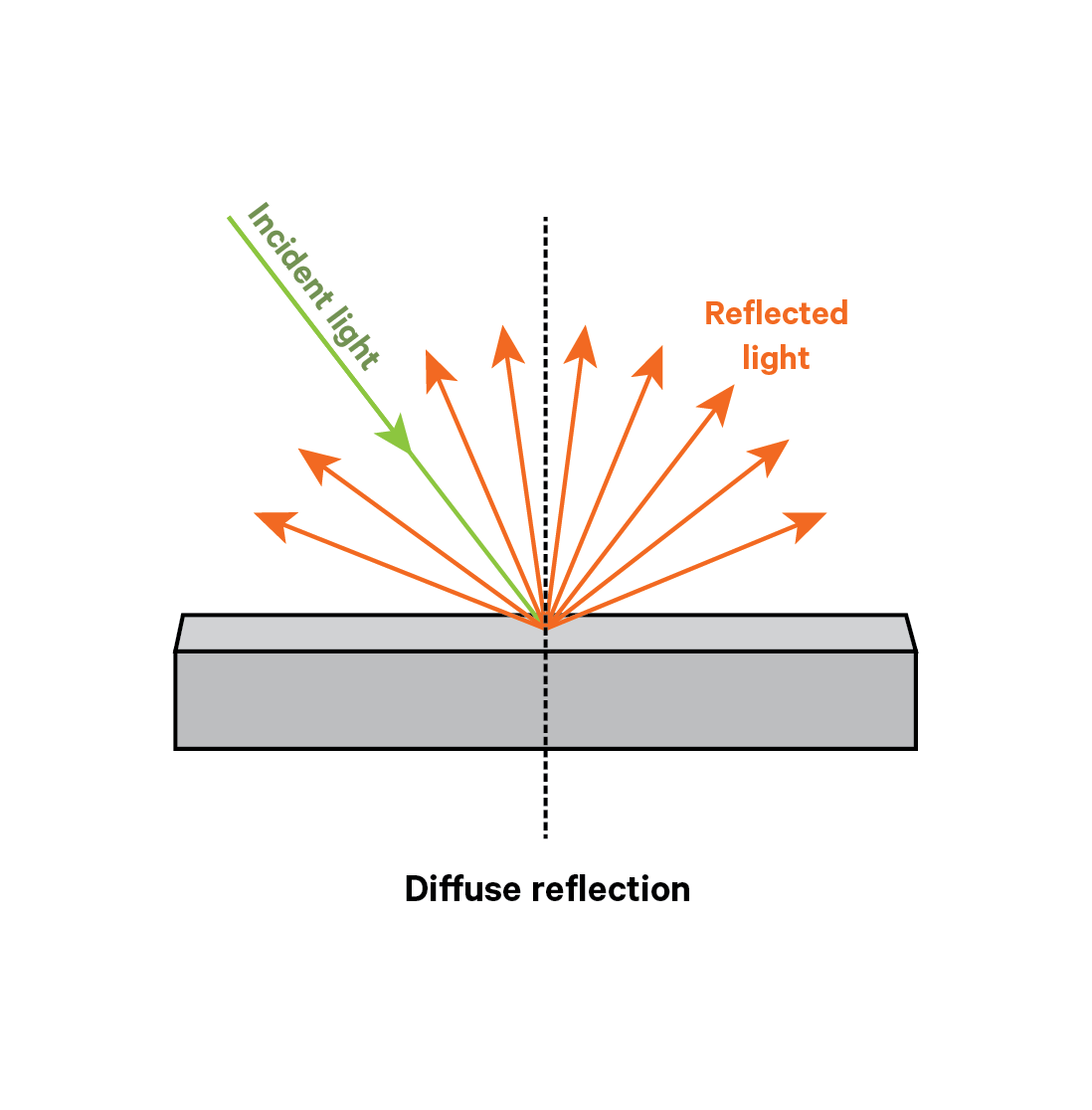

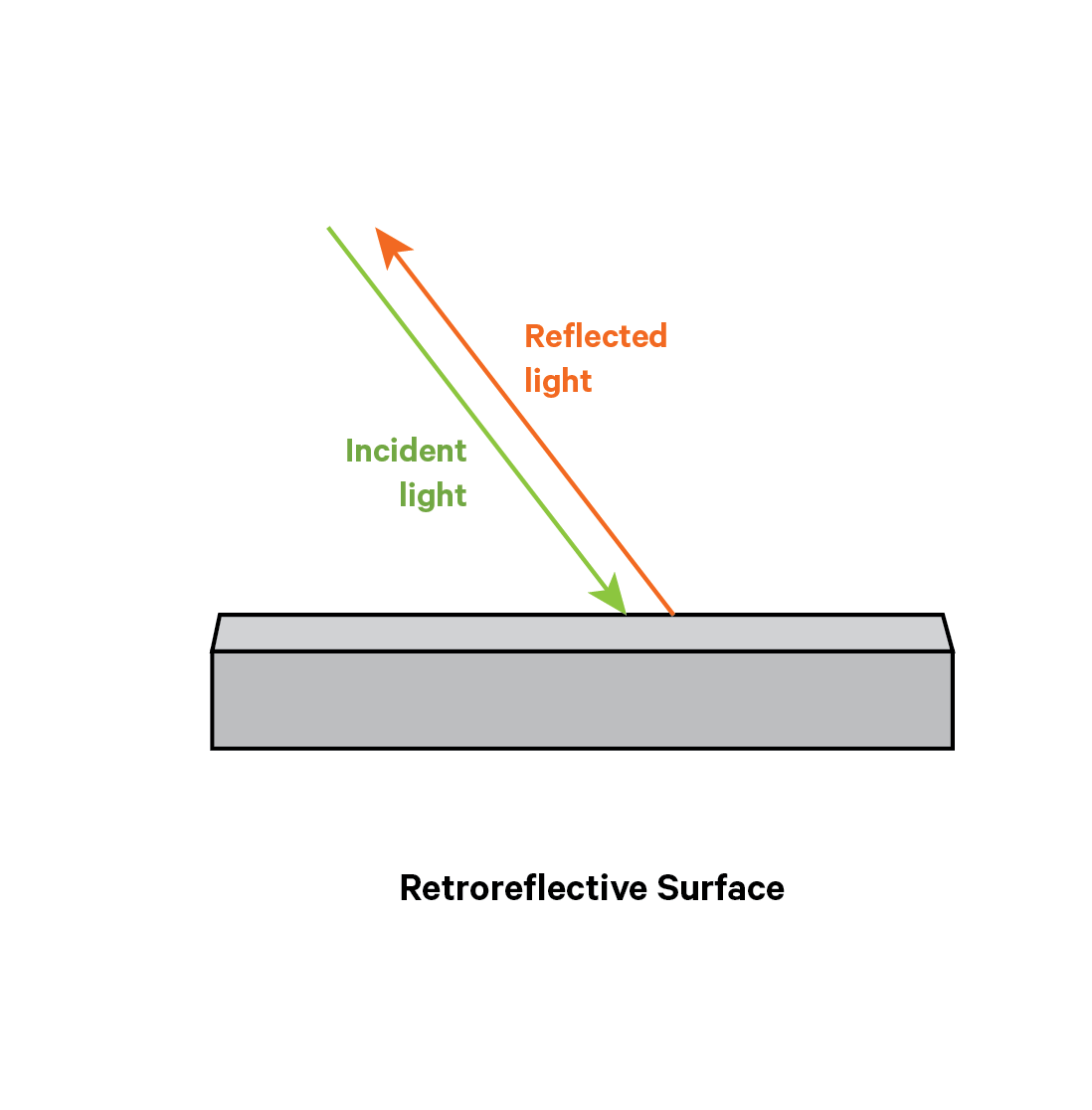

A retroreflector is a manufactured surface that sends light back toward its source. How objects reflect light depends on their surface qualities:

Specular (mirrorlike) surfaces reflect light away at equal angles—bright only when the beam hits square-on.

Diffuse (matte) surfaces scatter the reflected light in many directions.

Retroreflective surfaces use tiny glass beads or microprisms to return most of the incident light to its source, even when the surface isn’t perpendicular.

Retroreflectors don’t create any light, they just return it very efficiently. When illuminated by an external light source (headlights, flashlights, or even ambient daylight), they can appear extremely bright in situations where normal materials fade into the darkness.

For a retroreflector to be obvious to an observer, two conditions are required:

The surroundings need to be relatively dim compared to the illuminated retroreflector.

The light source must be roughly in line with the observer’s eyes—e.g., a vehicle’s headlights near the driver’s eyes, a flashlight held near eye level, or a large diffuse light source behind the observer (e.g. an overcast sky).

Retroreflectors reflect most brightly when square to the light source, and remain highly visible across a range of entrance angles—commonly up to ~40° off perpendicular—though intensity decreases as the angle increases.

Where retroreflectors really shine

To vehicle drivers - retroreflectors illuminated by headlights returned the light toward the vehicle—i.e., toward the driver’s eyes—creating a bright, high‑contrast target in a dark scene. Highway signs are specially engineered to account for headlight and driver eye heights vs. sign height.

Dim interiors with bright exteriors - In a warehouse, retroreflective tape on a person standing in shadow near a doorway can “light up” to an outside observer. This is because brighter daylight behind the observer is retroreflected off the PPE back to the observer.

Common applications

Roads & traffic control - Road signs, cones, barriers, and lane markers for nighttime and bad‑weather visibility.

Vehicle conspicuity - Trucks, trailers, buses, and emergency vehicles use conspicuity tape to outline their size and shape to drivers at night.

Worksites & warehouses - Forklifts, racking, posts, and fixed obstacles—increasing contrast and helping prevent vehicle strikes in low‑light settings.

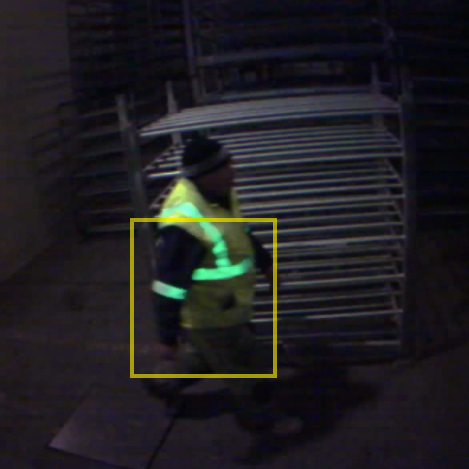

Personal visibility (PPE) - Retroreflective tape on garments to make people more visible in low light.

Active detection - Retroreflective tape acts as a tag to enable active detection by a SEEN IRIS 860 LiDAR sensor, even in dark, low‑contrast, or bright light conditions.

Types of retroreflective tape

Retroreflective material comes in two main types, each manufactured quite differently:

1) Exposed glass bead (common on hi‑vis PPE and garment trim)

Tiny glass beads are half‑coated with aluminum (forming hemispherical mirrors) and embedded in a binder. Incoming light refracts into the bead, reflects off the metallized back hemisphere, then exits along a path close to the source.

Typical properties

Appearance - Silver‑gray with slightly matte texture. Often laminated to a lightweight backing and sewn onto garments; heat‑transfer variants exist.

Performance - Bright white reflection; generally wide entrance‑angle performance.

Pros - Cost‑effective, soft and flexible, reasonably durable, easy to manufacture.

Cons - Beads can be lost to abrasion or laundering; wetting can reduce performance; lower peak brightness than premium microprismatic films.

Leading brands - 3M™ Scotchlite™ and a wide range of quality alternatives.

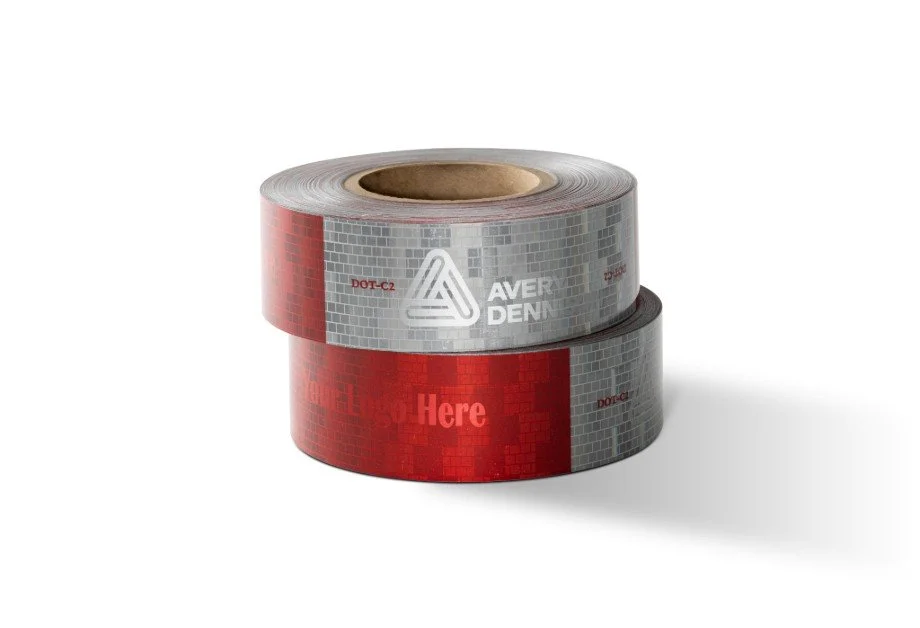

2) Microprismatic (common on road signs, vehicle markings, and some PPE)

High‑precision plastic film embossed with thousands of tiny corner‑cube prisms. Light reflects internally off two or three prism faces and returns toward the source.

Typical properties

Appearance - Smooth plastic sheet with fine prism texture.

Performance - Highest potential brightness; less affected by rain or surface wetting thanks to the smooth, sealed face.

Pros - Can greatly exceed the reflective intensity of glass‑bead materials; maintains performance when wet; can be colored; can be tuned for specific angular performance.

Cons - Higher cost; heat‑sensitive during application; low‑quality look‑alikes may appear similar but perform poorly.

Leading manufacturers - Avery Dennison, 3M, ORAFOL/Reflexite, Nikkalite.

Things to be aware of

Abrasion & laundering (glass bead tape)

Daily wear and repeated wash cycles can dislodge the reflective beads, gradually reducing reflectivity. Standards‑compliant PPE often specifies a maximum number of wash cycles (commonly ~50). Check the label and replace garments once worn areas start appearing dark when illuminated. Old or degraded trim can turn protective gear into merely colorful clothing.

Rain & surface wetting (glass bead tape)

Exposed glass‑bead reflective tape can trap water around the beads, reducing retroreflection and creating dark patches. Microprismatic tapes—sealed by a smooth plastic face—are less affected by rain.

Low‑quality, cheap microprismatic tape

Manufacturing high quality microprismatic sheets demands expensive, high precision tooling. Cheap microprismatic products can be made to look convincing, yet deliver very low retroreflective performance.

For critical applications (e.g., vehicle conspicuity, high‑value asset marking, or reflective safety harnesses), choose reputable brands that meet relevant US and international standards—and verify performance with a quick flashlight/headlight, or IRIS 860 sensor test.

Left: Generic low-cost microprismatic tape—looks 100% convincing, but is only 10% as bright. Not fit for purpose for safety critical applications.

Right: Genuine 3M™ microprismatic—higher cost, but 10x brighter than its cheap lookalike.

What’s next?

If people at your workplace already use retroreflective PPE, you’re halfway there. The SEEN System turns this base-level passive safety control into an active, engineering control for forklifts and other MHE—helping to safeguard your people and your business.

Want a quick demo or site assessment? Get in touch.