Manager’s introduction to the SEEN Safety System

If you are responsible for managing vehicles that have been fitted with a Seen Safety System, the following information may be useful to you.

The SEEN Safety System includes the IRIS 860 sensor and the IRIS-i camera, along with the SEEN Insight data platform, providing an active alert system and crucial visual evidence for better safety decision making.

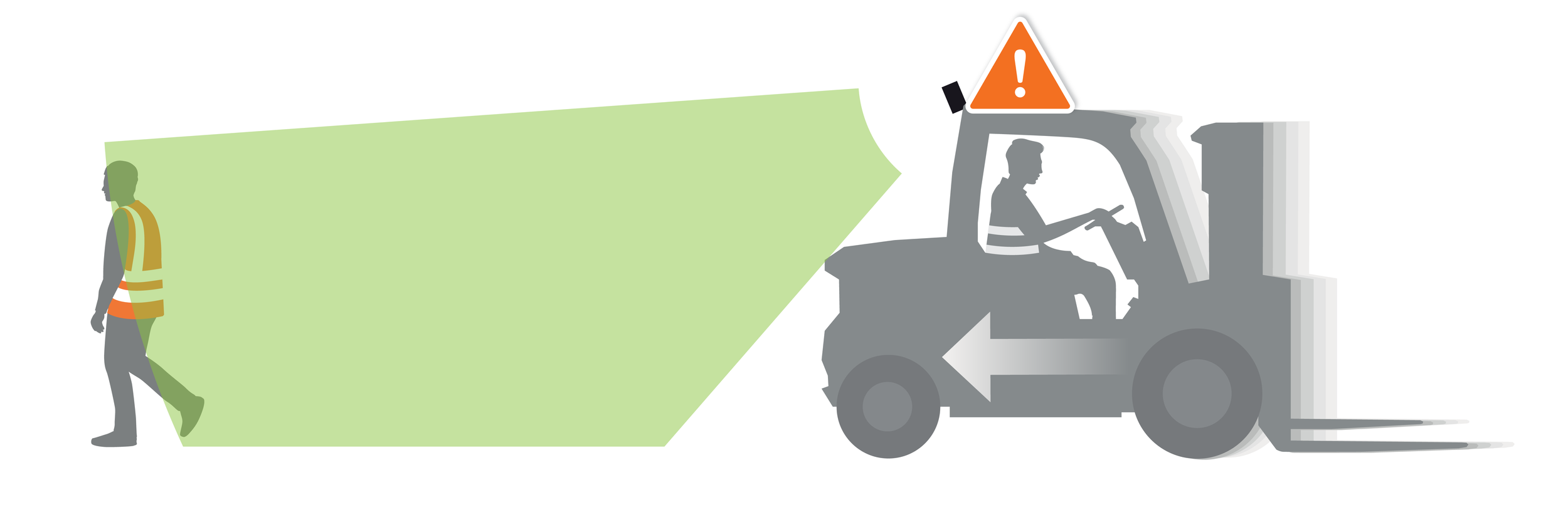

How does the sensor work?

The IRIS 860 sensor uses infrared technology to detect reflective tape on high-visibility workwear, or on an object marked with reflective tape. When the sensor registers someone or something marked with high-viz that gets too close to the machine, it gives a loud audible alert to both driver and pedestrian. It is an extremely effective way to minimise accidents and injury in the workplace.

Watch SEEN’s videos below to learn how the sensor works.

How can you ensure the sensor is optimised for your workplace?

The sensor’s detection zone settings and alert volume can be changed to suit your operating environment. It is an easy and straightforward process you can learn and do effortlessly.

You can learn more about the sensor settings and how to change them, in the sections below.

Retro-reflective tape requirements

To be detected by an IRIS 860 sensor, pedestrian workers must being wearing workwear with retro-reflective tape.

IRIS 860 sensors work best when the main source of reflective tape is on high-viz vests worn by people, or on objects specifically tagged for detection. If your site has a lot of traffic cones, bollards, or reflective signs that could activate the IRIS 860 sensor and cause irrelevant alerts, consider how this can be managed. Too many non-relevant detections will result in operator annoyance and undermine the effectiveness of the system.

Please refer to the Reflective Tape Requirements for more details.

If you have any questions or concerns please contact SEEN customer support.

IRIS 860 sensor settings

The sensor’s detection zone settings and alert volume can be changed to suit your operating environment.

Key sensor settings

Critical alert zone. On a forklift, this is often set to be between 3m (9ft) and 4m (12ft). The exact distance to pre-set depends on the working environment and machine type. On larger machines like wheel-loaders, 5m-8m is common. Detection in this zone results in a continuous loud audible alert.

Early-warning zone. The early warning zone (beeping alert) indicates that the critical alert zone is getting close.

Reverse-only activation. To avoid irrelevant detections, sensors mounted on the rear of the forklift are frequently pre-set so they can only alert when the machine is in reverse gear.

Alert Volume. This alert is intentionally loud, but can be reduced if necessary.

Learn more about the sensor settings.

Instructions on how to change the sensor settings.

IRIS 860 sensor and the SEEN sensor setup app.

Setting the right detection zone

The SEEN Safety system gives you the flexibility to adjust the detection zones to meet your workplace requirements. While it is critical that the detection distance is set to alert before a person gets dangerously close to the machine, it is equally important that the detection zone is not set too large because this may result in irrelevant detections that could annoy the operator. Achieving this careful balance may require some experimentation.

There are five main aspects to consider when setting the detection zone:

Where should detection be targeted?

At what distance should the alarm be activated?

Is an early-warning alert needed?

What shape should the detection zone be?

Should detection be dependent on the machine’s direction of travel?

For more information about each aspect, please refer to the SEEN IRIS 860 Detection Zone Guide (PDF)

Setting the alert volume

If the sensor is mounted close to the driver’s head, the sensor’s alert tone may be uncomfortably loud (94dB at 1m). Although the alarm is loud it is not harmful to hearing, even with prolonged exposure.

The alert tone is deliberately loud to motivate positive behaviour change.

If the operator asks if the alarm can be made quieter, tell them, ‘Yes the simplest way to do this is to maintain a safe distance from pedestrian workers!’

If the driver complains that the alert is too loud, this could be symptomatic of:

Too many irrelevant detections. In this case, refine the detection area and/or reduce the amount of unnecessary reflective material in the environment.

Too many pedestrians in the critical risk zone. This is a safety issue and needs to be addressed.

If the alert volume is an issue, the settings can be changed. Please refer to Changing the Sensor Settings for further details.

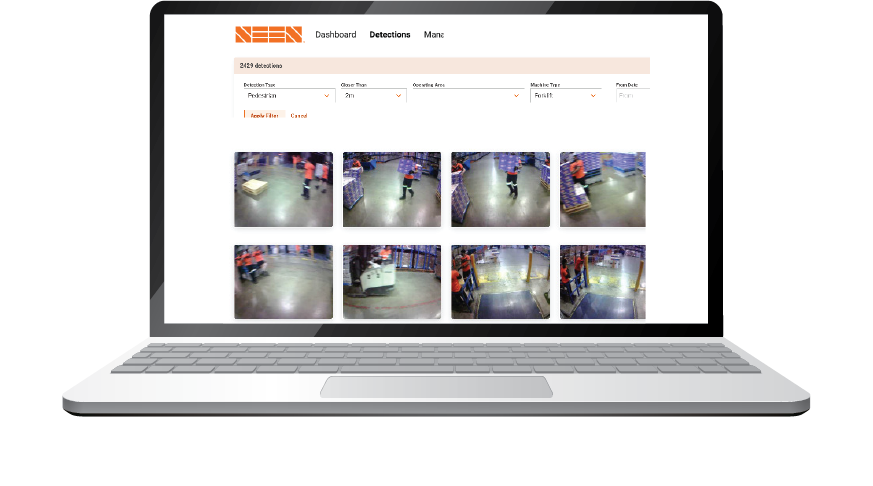

IRIS-i camera / SEEN Insight: a reliable eyewitness

The sensor may be fitted with an IRIS-i camera. When the sensor makes a detection, the IRIS-i camera captures an image and short video of the detection event, along with relevant data such as the detection time, date, duration, and detection distance.

The captured data is securely uploaded to SEEN's online app, SEEN Insight, through the mobile data network. By logging into SEEN Insight, you can see detailed detection information and real-time data, enabling you to gather valuable insights about near-miss accidents, pedestrian traffic patterns, and high-risk areas.

Please read the SEEN Insight User Guide which covers how to set up your SEEN Insight workplace account, and how to manage and activate IRIS-i cameras.

If you need help setting up your SEEN Insight account or activating your IRIS-i camera, please contact support@seensafety.com.

SEEN Insight

IRIS 860 sensor and IRIS-i camera