Is 360° Detection Really Right for Your Machines?

A single moment of inattention around a forklift can have devastating consequences. These vital but unforgiving machines rank among the most serious on-site hazards. According to the UK’s Health & Safety Executive, five people suffer life-changing forklift injuries every day.

The law requires PCBUs to take all reasonably practicable steps to control this risk. When full separation of pedestrians and material-handling equipment isn’t possible, many safety managers are turning to engineering controls—such as proximity detection—to strengthen their hierarchy of controls.

If you’re exploring proximity detection technologies, the options can be overwhelming. Fear of choosing the wrong system often leads to delays—and continued exposure to risk. While no technology is a silver bullet, research shows that deploying the right system within a proactive safety culture can reduce incident rates by more than 80%, preventing injuries and saving lives. The key is finding the right combination of features, performance, and practicality to deliver meaningful, long-term safety improvements for your site.

Two Common Assumptions Worth Challenging

Before selecting a system, question two widely held assumptions:

1. Detect any object in the forklift’s path

No one wants their forklift hitting people, pallets, or infrastructure, right?

2. Provide 360° detection around the vehicle

Intuitively, it seems safer if the entire area around the machine is monitored.

Let’s unpack each.

Detect Any Object in the Forklift’s Path

Detection often relies on radar, which emits signals that bounce off obstacles. Sounds sensible—but in practice, it generates a high volume of irrelevant alerts—from walls, racking, or nearby equipment—that quickly become background noise. Operators grow accustomed to ignoring these alerts, and the system’s effectiveness drops dramatically.

Imagine a person suddenly appearing between a reversing forklift and a wall. Radar can’t distinguish them from the wall, and the operator—assuming it’s just another false alert—may ignore the alarm entirely.

Key Lesson 1: If protecting people is your main priority, radar isn’t enough.

You need selective detection that identifies only people (or specific objects of interest). Options include AI-based human-form detection cameras, RFID tag systems, and SEEN’s IRIS technology.

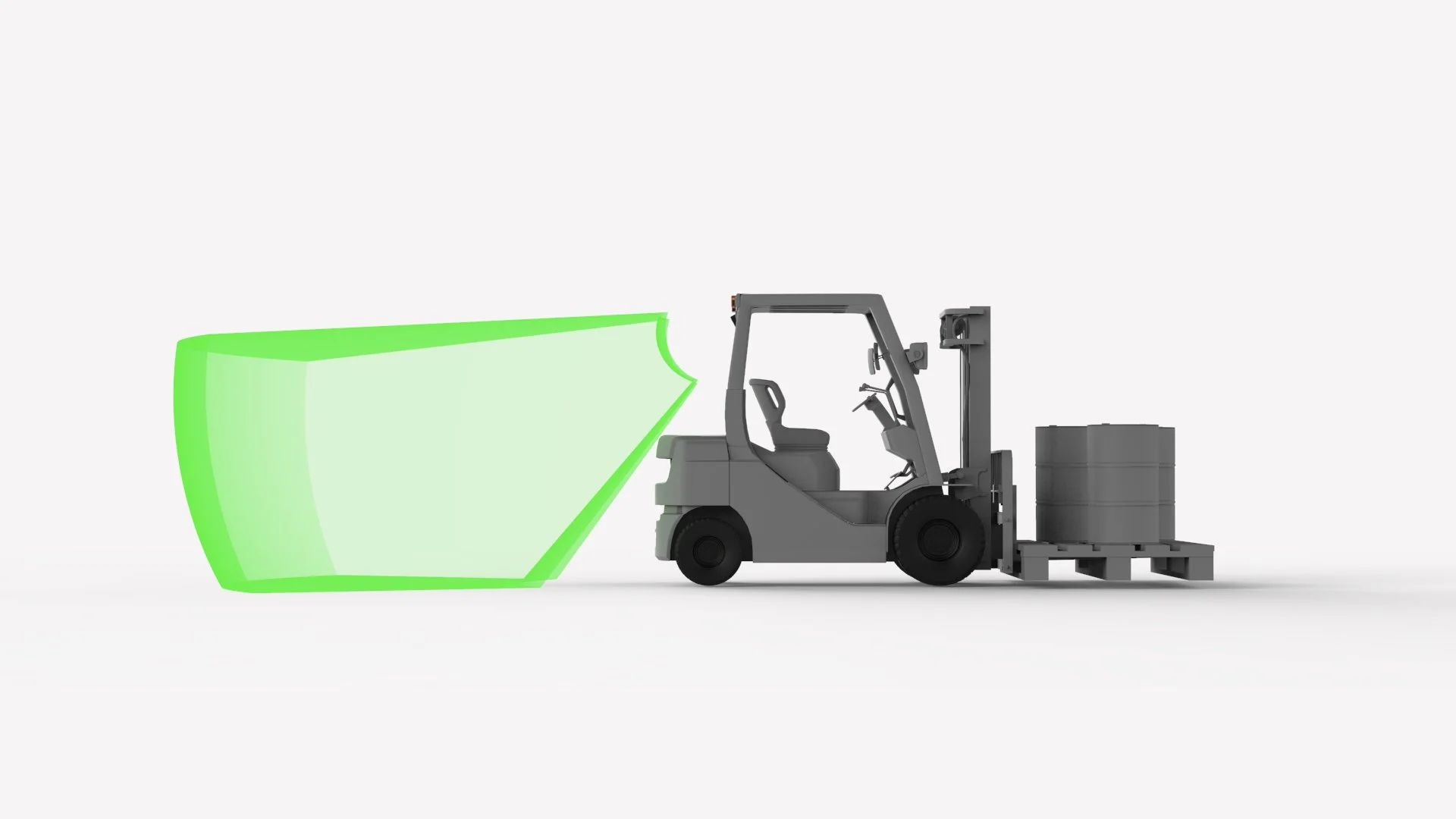

360° Detection Around the Vehicle

360° AI cameras and RFID tags are popular for proximity detection, alerting when someone enters a pre-set safety zone. But in real-world operations—where people often need to work near equipment—these systems overwhelm operators with unnecessary alerts. Many warnings are triggered by people who are clearly visible to the driver or not in harm’s way, eroding trust in the system.

Constant over-alerting dulls awareness and undermines response during genuinely high-risk moments, such as when someone is hidden in a rear blind spot. Since forklifts can’t move sideways, alerts for people alongside the machine often make little sense.

Key Lesson 2: The biggest problem with 360° systems is over-detection.

Seek systems with targeted, customisable detection zones focused only on genuine high-risk areas.

Beware the Override Button

If a system includes an override button, proceed with caution. Its presence usually signals over-detection—operators are expected to silence irrelevant alerts. In practice, many drivers end up holding the button down all day, effectively disabling the system. When detection is tied to machine control, this creates operational inefficiencies and serious safety risks.

In Summary

Over-detection is the number one factor that undermines pedestrian detection systems. Frequent false alerts desensitise both drivers and pedestrians, increasing the chance of serious incidents. The goal: just enough detection to be meaningful—no more, no less.

A Smarter Way Forward

The good news: SEEN understands what makes a detection system practical and effective. The IRIS 860 sensor dramatically reduces over-detection by selectively identifying retroreflective surfaces and narrowing its detection field to a precise 60° zone—focused only on the highest-risk area. Compared to a 360° system, it produces up to 84% fewer irrelevant alerts, letting operators stay focused on what truly matters: keeping people safe.